Cable Carriers and Conductor Bars Designed to Withstand Extreme Conditions in Galvanizing Plants

VAHLE offers an extensive portfolio of solutions designed to meet the distinctly harsh conditions in galvanizing plants. Our festoons/cable carriers and conductor bars can withstand the harsh chemicals and high temperatures — including extreme heat — present during the manufacturing and treatment process. These products feature stainless steel and PVC plastic to minimize galvanic corrosion and support efficiency and productivity.

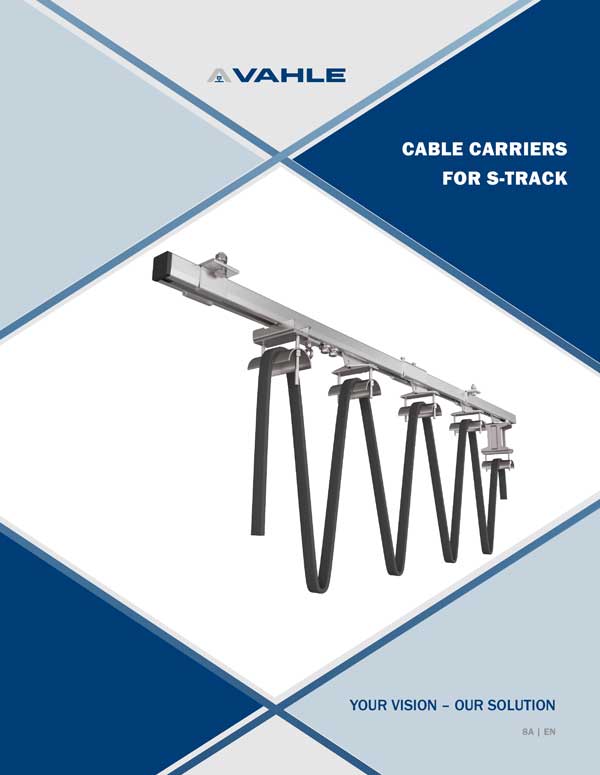

Our acid- and corrosion-resistant festoons and time-tested conductor bars are designed to provide a reliable, uninterrupted power supply to electric hoists, heavy-duty galvanizing cranes and interlocking crane systems. In general, our recommended festoons are resistant to abrasive dust, acid and salty atmospheres present during the degreasing, pickling and fluxing processes. We offer both traditional cable carriers that rely on wheels and a special gliding cable carrier made of PVC plastic that allows for peak performance during the true galvanizing process.

Material Handling in Galvanizing Plants

Galvanized metal/fabrication is a complex metallurgical process conducted via hot-dip galvanizing after fabrication or continuous hot-dip galvanized sheets. While each process requires specific equipment and is better suited to specific applications, both require reliable material handling to output high-quality materials.

VAHLE’s products are optimized for these metal/fabrication processes and can be used for various stages. For example, our conductor bars power the overhead cranes used to transport materials between surface preparation and galvanizing bath stations, and to cooling stations, drying racks or electric hoists. For lighter fabrications that are hung to dry, such as metal sheets, our festoons are ideal for transportation of pre- and post-treatment galvanized products. Our gliding cable carrier is ideal for applications up to 30 meters (~100 feet) and weight capacity up to 5 kg (11 pounds) per cable carrier. For longer or heavier applications, we also offer a stainless-steel cable carrier that can support applications up to 60 meters (~200 feet). Our stainless-steel carriers with wheels, designed for stainless-steel C-track, have a weight capacity up to 55 kg (~120 pounds) per carrier and are ideal for long systems with curves.

Benefits

- Acid and corrosion resistance

- High-heat resistance

- Reduce maintenance and system costs

- Mitigate labor risks and wiring errors

- Improve reliability and capacitance

- Minimize galvanic corrosion and appearance imperfections

Product highlights

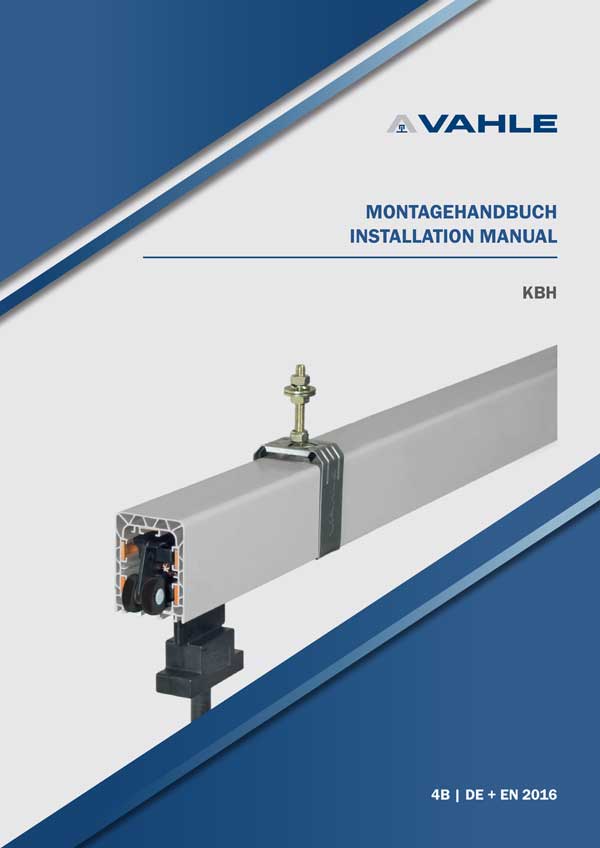

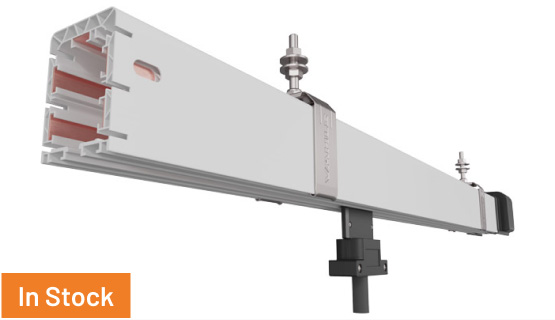

KBHF/KBHS Enclosed Conductor Rails with Sealing Strips

- 63A – 200A

- 4 – 5 Copper conductors in plastic housing.

- Resistance to chemicals at 45°C (113°F): Gasoline, mineral oil, grease, sulfuric acid up to 50%, caustic soda up to 50% and hydrochloric acid up to 25%, concentrated.

- Optional curves, transfers and switches.

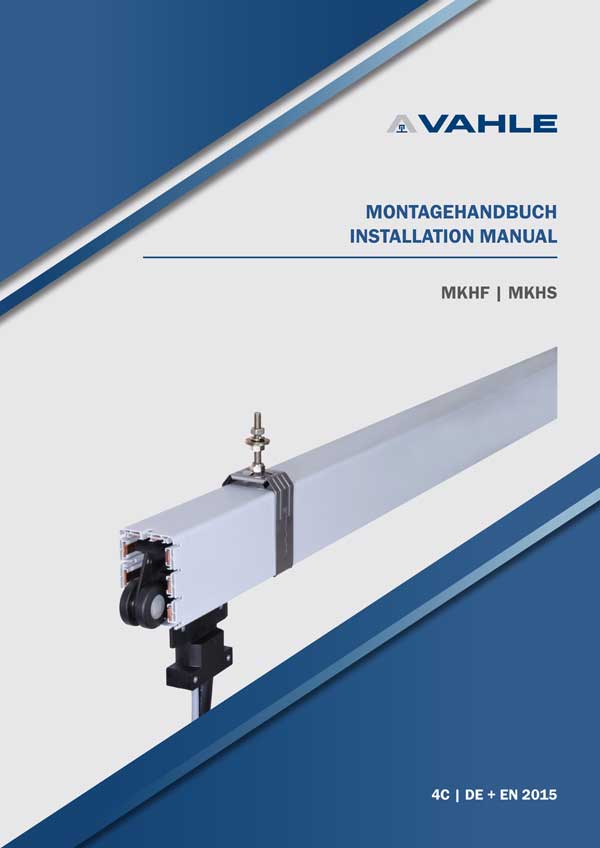

MKHF/MKHS Enclosed Conductor Rails with Sealing Strips

- 63A – 200A

- 6 – 10 Copper conductors in a plastic housing.

- Resistance to chemicals at 45°C (113°F): Gasoline, mineral oil, grease, sulfuric acid up to 50%, caustic soda up to 50 % and hydrochloric acid up to 25%, concentrated.

- Optional curves, transfers and switches.

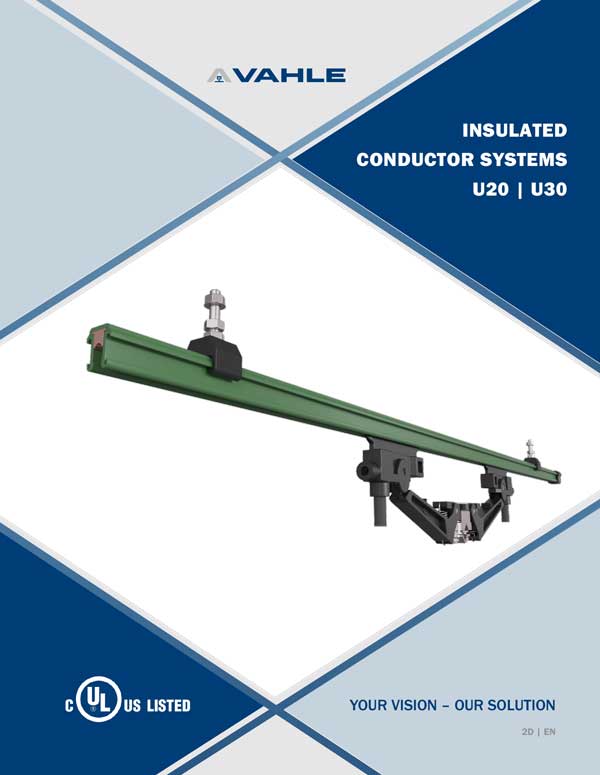

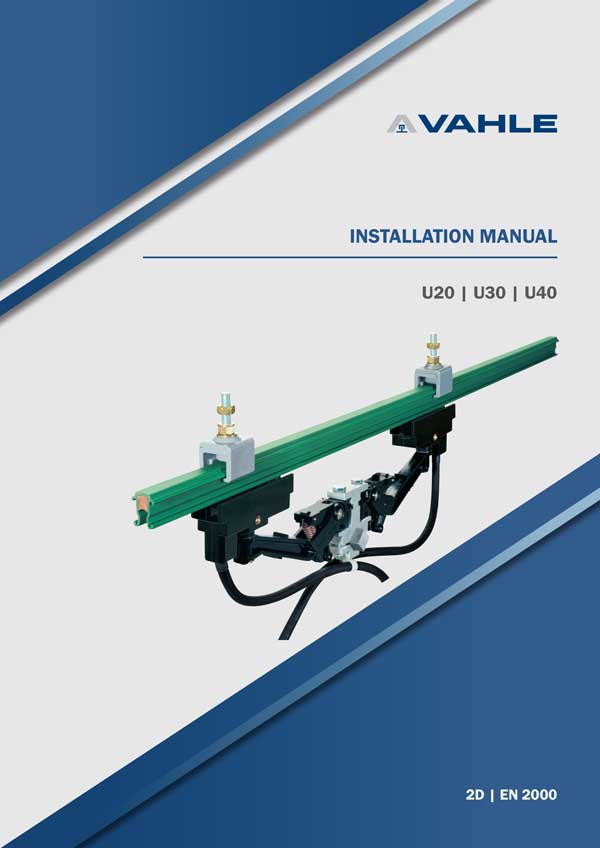

U20 and U30 Heavy-Duty Unipole Conductor Rails

- 210A – 530A

- Durable plastic shrouding and solid copper conductors.

- Resistance to mineral oil, fats, caustic soda up to 25%, hydrochloric acid up and sulfuric acid up to 50%, concentrated.

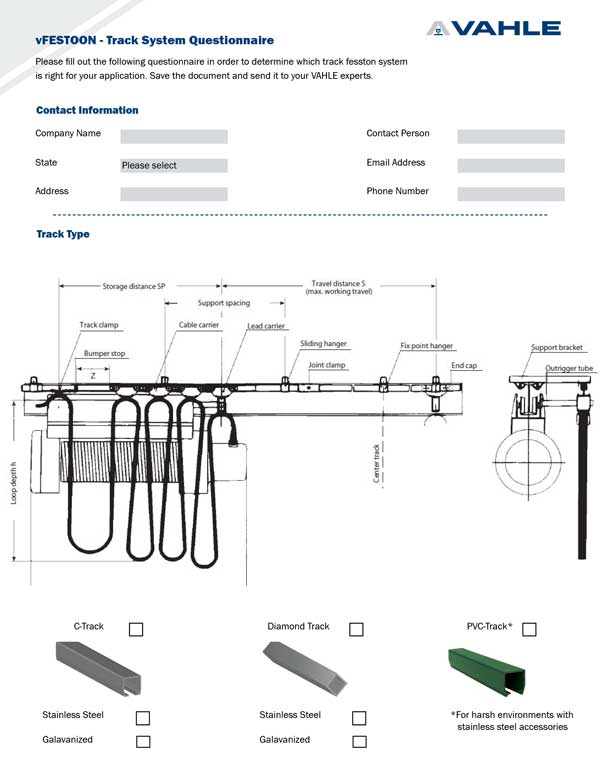

Festoons

- Plastic profile, plastic gliding carriers or stainless-steel carriers with wheels for K1 track.

- Stainless-steel track and/or cable carriers for C-track.

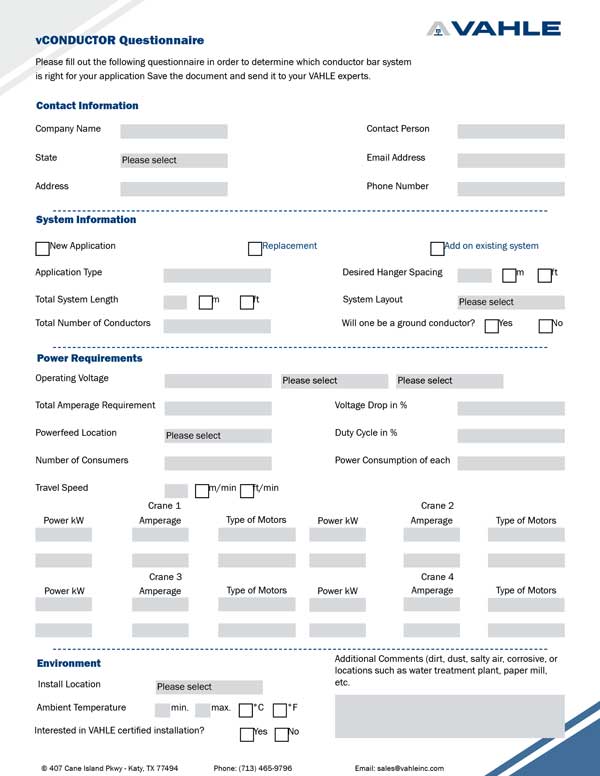

"*" indicates required fields